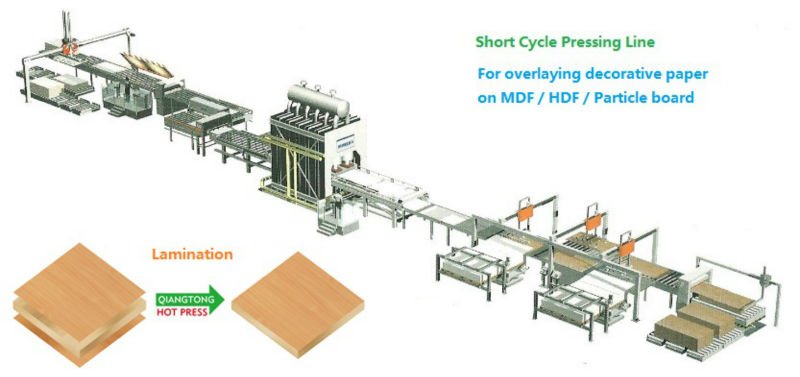

laminating production line

Product Description

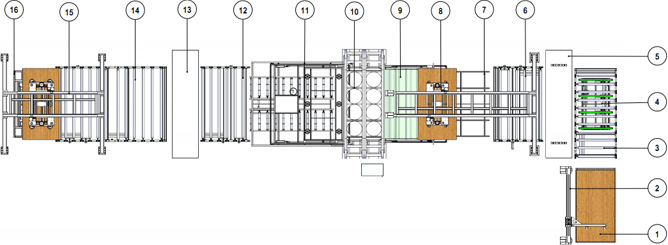

Description of tpu film laminating production line

1 | Name | Specification |

2 | Total pressure (KN) | 28000(2800T) |

3 | Specific pressure (kg/cm2) | 37.7KG/cm² as per platen size |

4 | Finished product size(mm) | 1830x3660 |

5 | Main cylinder diameter(mm) | 420mm*300mm |

6 | Main cylinder stroke | 250mm |

7 | Main cylinder units | 8 |

8 | Lift cylinder diameter(mm) | 100x60X300mm |

9 | Lift cylinder stroke | 250mm |

10 | Lift cylinder units | 4 |

11 | Hydraulic system pressure | 25mpa |

12 | Hot plate size(mm) | 3800*1950 |

13 | Up Hot plate thickness(mm) | 180mm |

14 | Down Hot plate thickness(mm) | 180mm |

15 | Hot platen temperature | 0—250o adjustable |

16 | Temperature difference | ±1.5o |

17 | Heating medium | Heating oil 30Kcal/Hour |

18 | Control mode | PLC Mitsubishi auto/manual |

19 | Total power (KW) | 22kw |

20 | Overall dimension(LXWXH mm) Composite structure with 80mm frame thickness (two parts) | 3150*3800*2730 |

21 | Whole line net weight | Approx.95T |

22 | Daily output (piece/day) | 1000—1200 sheet |

23 | Temperature control valve | 2 pcs of sensor (Germany BAELZ) & 2nd circuit oil system Electronic valve: Italy ATOS |

24 | Template hook | 1 set |

25 | The electrical box | Touch screen Mitsubishi PLC |

26 | Big fuel tank | With inside cooling system |

27 | Hydraulic pump station | Taiwan valves |

28 | Cycle working time | Less than 55 seconds |

29 | Assisting time: less than 10s, including closing time, pressure increasing time, pressure releasing time and cylinder lifting time |

30 | Loading speed | About 50m/second |

31 | Unloading speed | About 50m/second |

32 | Loading/unloading trolly gear precision | >=50% |

If you need this machine's any information, please feel free contact me.

Welcome to visit our factory, and we will show you this kind machine.

Also we can send you this press's video!

Picture of tpu film laminating production line

Our Services

Our services:

Pre-sale services: hot press

1> Provide the free consultation of the equipment

2> Provide the standard device and the flow chart

3> According to the clients’ special requirement, offering the reasonable plan and free design helping to select the equipment. hot press

4> Welcome to visit our factory

Services during the sales: hot press

1> Inspect the machine before leaving the factory.

2> Oversea install and debug the equipment

3> Train the first-line operator.

Company Information

Weihai Reliable Imp&Exp Corp., Ltd is located in Linyi city, Shandong province, China, where is famous for the wooden panels and woodworking machinery. Our company was established in 2004, and have been engaged in the manufacturing and supply of woodworking machines since then, Including plywood production machinery, Particle Board production machinery (Linyi Factory), short cycle lamination machinery (Wuxi Factory) and other relevant machinery, and our customers are coming from all round the world, like India, Vietnam, Indonesia, Bangladesh, Sri Lanka, Saudi Arabia, Malaysia, Iran etc.

Our company has more than 10 experienced mechanical and electrical engineers, and they mainly focus on the research and development of the woodworking machinery. Meanwhile our factories are fully equipped with advanced lathe machine, grinding machine, planner and welder, which together contribute to the high precision machinery. Also we have a very strong and experience after-sale team, they are doing all commissioning and maintenance work for our customers.

Our company culture is “Quality is our for-ever goal, after-sale Service is our priority, win-win with customers”, and we would like to cooperate with the friends from all around the world.

FAQ

If you need this machine's any information, please feel free contact me.Welcome to visit our factory, and we will show you this kind machine.Also we can send you this press's video!How to Contact Us? Send your Inquiry Details in the Below for free sample , Click "Send" Now!tpu film laminating production line